The function of vacuum system in edible oil refinery plant

The function of vacuum system in edible oil refinery plant is to provide the vacuum condition for decolorization and deodorization process. The decolorization and deodorization process are the most important sections in edible oil refining process, and the stability and reliability of vacuum system are the main factors to obtain high quality product oil.

GET PRICE

VACUUM SYSTEMS IN THE EDIBLE OIL INDUSTRIES

Multi-Stage Ejector Vacuum System Today nearly exclusively those ejector systems are used in the edible oil industry world wide. The advantages are obvious: - large mass flows can be moved within acceptable plant sizes and sensible steam requirement figures ,the two stages jet ejector,the three stages jet ejector and the four stages jet ejector.Between two stage of ejectors equips with an inter condenser which can choose two types of

GET PRICE

Vacuum systems, petrol, refineries, oil, gas, jet pump

Vacuum column in an oil refinery with two Körting steam jet vacuum ejectors and downstream surface condensers Higher yield of light products Due to the two distillation processes, there is a clear yield ratio between each of the products generated from a certain type of crude oil.

GET PRICE

Edible oil refinery vacuum system Manufacturer, Supplier

We offer varieties of pump products, including an extensive range of pump. Request our products at the best rate possible and save money

GET PRICE

high configuration edible oil processing plant

Edible Oil Refinery Plant Manufacturers and Exporters In India. ... The function of vacuum system in edible oil refinery plant_Tech. In a word, if you want to get high quality product oil, the vacuum system in edible oil refinery plant is necessary. When you buy edible oil refinery machine, you had better take a good look at the configuration

GET PRICE

Edible Oil Refinery Machine Technology | Myande Group

Edible Oil Refinery Technology. The objective of refining is to remove objectionable co-constituents in edible oil with the least possible damage to glycerides and minimal loss of desirable constituents. Methods of refining depend on nature and quantity of impurities contained in crude oil, application of RBD oil.

GET PRICE

Bleaching Process - Edible Oil Refinery, Vegetable Oil

The process variables such as moisture levels, temperature, contact time, vacuum are reliant parameters in oil purification process to determine achieve high quality refined oil product. The activated bleaching clays have increased bleaching efficiency and impurity removal rate as compared to normal one.

GET PRICE

Refining of Edible oils: Edible Oil Processing

Two processes have been developed for the refining of edible oils and fats, i.e. physical and chemical refining; the decision which process to use depends on the types and qualities of the crude oil to be processed .The names physical and chemical refining come from the process technology used to remove the Free Fatty Acids that are responsible for the oil acidity.

GET PRICE

The function of vacuum system in edible oil refinery plant

The function of vacuum system in edible oil refinery plant is to provide the vacuum condition for decolorization and deodorization process. The decolorization and deodorization process are the most important sections in edible oil refining process, and the stability and reliability of vacuum system are the main factors to obtain high quality product oil.

GET PRICE

VACUUM SYSTEMS IN THE EDIBLE OIL INDUSTRIES

Multi-Stage Ejector Vacuum System Today nearly exclusively those ejector systems are used in the edible oil industry world wide. The advantages are obvious: - large mass flows can be moved within acceptable plant sizes and sensible steam requirement figures ,the two stages jet ejector,the three stages jet ejector and the four stages jet ejector.Between two stage of ejectors equips with an inter condenser which can choose two types of

GET PRICE

Vacuum systems, petrol, refineries, oil, gas, jet pump

Vacuum column in an oil refinery with two Körting steam jet vacuum ejectors and downstream surface condensers Higher yield of light products Due to the two distillation processes, there is a clear yield ratio between each of the products generated from a certain type of crude oil.

GET PRICE

Edible oil refinery vacuum system Manufacturer, Supplier

We offer varieties of pump products, including an extensive range of pump. Request our products at the best rate possible and save money

GET PRICE

high configuration edible oil processing plant

Edible Oil Refinery Plant Manufacturers and Exporters In India. ... The function of vacuum system in edible oil refinery plant_Tech. In a word, if you want to get high quality product oil, the vacuum system in edible oil refinery plant is necessary. When you buy edible oil refinery machine, you had better take a good look at the configuration

GET PRICE

Edible Oil Refinery Machine Technology | Myande Group

Edible Oil Refinery Technology. The objective of refining is to remove objectionable co-constituents in edible oil with the least possible damage to glycerides and minimal loss of desirable constituents. Methods of refining depend on nature and quantity of impurities contained in crude oil, application of RBD oil.

GET PRICE

Bleaching Process - Edible Oil Refinery, Vegetable Oil

The process variables such as moisture levels, temperature, contact time, vacuum are reliant parameters in oil purification process to determine achieve high quality refined oil product. The activated bleaching clays have increased bleaching efficiency and impurity removal rate as compared to normal one.

GET PRICE

Refining of Edible oils: Edible Oil Processing

Two processes have been developed for the refining of edible oils and fats, i.e. physical and chemical refining; the decision which process to use depends on the types and qualities of the crude oil to be processed .The names physical and chemical refining come from the process technology used to remove the Free Fatty Acids that are responsible for the oil acidity.

GET PRICE

Oil Refinery Process Units, Refinery Equipment List

Oil refining processes are the chemical engineering processes and other facilities used in petroleum refineries to transform crude oil into useful products such as liquefied petroleum gas , gasoline or petrol, kerosene, jet fuel, diesel oil and fuel oils.

GET PRICE

Oil Refiner Plant Project Producing the Puriest Edible Oil

Oil Refinery Plant Introduction. Oil Refining is a progress of removing the impurities such as phospholipids, FFA, pigment, off-flavor in cruel oil before edible application. Oil refining machine is used for producing the first or second-grade edible oil. We are able to supply the professional oil refining plant and related oil refining equipment.

GET PRICE

Edible Oil Refinery, Edible Oil Refinery Plant, Edible Oil

Edible Oil Refinery and Edible Oil Refining have been the areas of excellence for TINYTECH UDYOG. We are based in India and since 1990 we have been the Basic Designers, Manufacturers and Exporters of complete Edible Oil Refinery Plants to convert the crude oils into pure RBD oils.

GET PRICE

FAQ about vegetable oil processing technology - Oil Extraction

In vegetable oil refining process, using steam take the bad smell off in high temperature and vacuum conditions. The deodorization tower in semi- continuous vegetable oil refining plant [Related reading: The importance of steam deodorization in edible oil refining process] 5) Dewaxing and fractionation section in vegetable oil refining process:

GET PRICE

Physical and Chemical Process in Palm Oil Refining Plant

In order to get the pure and refined oil, there are three main process in chemical palm oil refinery plant and chemical palm kernel oil refinery plant: degumming process, bleaching process and deodourising process.. According to the degree of automation, the refinery process can also be divided into Batch Refinery Plant, Semi-continuous Refinery Plant and Continuous Refinery Plant.

GET PRICE

What is the vegetable oil refining process? - Edible Oil

Acid Oil Plant : Next step in Edible Oil Refinery is the Acid Oil Plant. We has designed an Environmental Friendly process for Acid Oil Plant and acid oil obtain from soap stock which coming from Alkali Refining of Oils and Fats etc. Soap Stock contain wash water, Bad quality of recovered oil.

GET PRICE

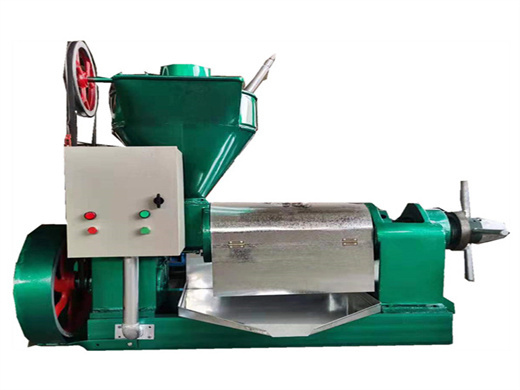

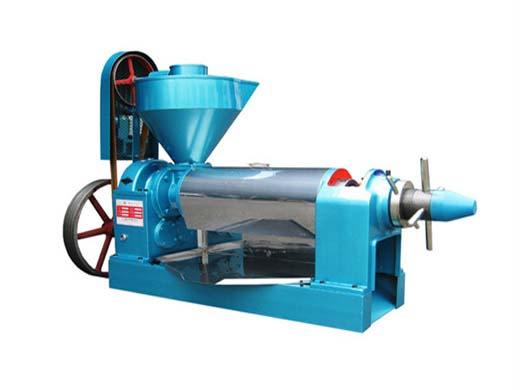

Edible Oil Refinery Plant - Mini Oil Refinery Plant

Batch Type Oil Refinery Plant is suitable for small scale refinery plants ranging upto 50-TPD. The batch type oil refinery plant is low-cost and easy to operate system. It can very easily and efectively refine different types of crude oils like groundnut oil, sesame oil, cottonseed oil, sunflower oil, palm oil, coconut oil, castor oil, rapeseed oil, mustard oil etc.

GET PRICE

Edible Oil Refinery Plant Manufacturers and Exporters In

Process Description of Edible Oil Refinery Plant. As per the today market research it is being concluded that the market demands the refined edible oil with characteristics such as bland flavour and odour, clear appearance, light colour, Long Shelf Life, Suitable for frying since the Crude Oil obtained does contains many harmful factors like free fatty acids , sediments, gums, odoriferous

GET PRICE

high quality 1 30tpd vegetable oil refinery plant

The function of vacuum system in edible oil refinery plant_Tech. In a word, if you want to get high quality product oil, the vacuum system in edible oil refinery plant is necessary. When you buy edible oil refinery machine, you had better take a good look at the configuration in the list, because some . Get Price

GET PRICE

Vacuum distillation is a key part of the petroleum

Vacuum distillation produces several types of gas oil. These are slightly heavier than middle distillates such as jet fuel, kerosene, and diesel. In the next stage of refining, these gas oils are further refined to make products such as light-cycle oil , gasoline, and naphtha.

GET PRICE